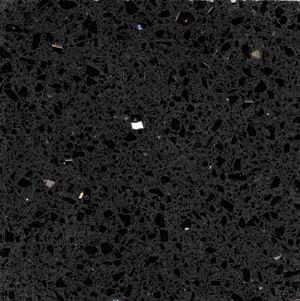

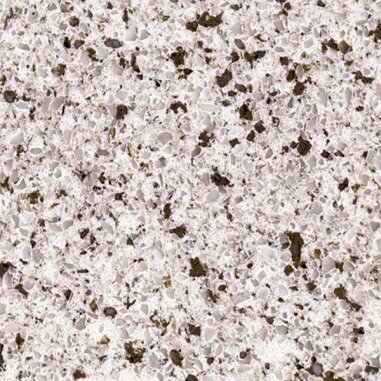

At present, quartz stone has been widely used in the whole building decoration. Because artificial quartz stone is wear-resistant, scratch resistant, high temperature resistant, corrosion-resistant, impermeable, non-toxic, radiation-free and zero formaldehyde, it can be used as food grade environmental protection table, etc. Quartz stone is rich in color, adjustable in appearance and as hard as natural stone. Therefore, the processing and manufacturing of quartz stone is different from that of ordinary artificial stone, especially for seamless splicing. Many people will recommend that we use the resin glue distributed by quartz stone manufacturer for splicing, which often does not solidify for a long time in use. What is the cause?

The reasons for the non setting of glue are as follows:

1. The workers did not mix the glue strictly according to the proportion during the construction. If they did not mix the glue evenly according to the proportion, they would not dry. If the time was long, they would pollute the stone!

2. It is not modulated according to the environment (temperature and humidity) at the construction site, and the resin glue is used with quartz powder and curing agent. Therefore, there are certain requirements for temperature and humidity, and the amount of curing agent added should change accordingly.

3. Water in the glue, or construction in rainy days and humid areas, is also a cause of slow glue curing. In this case, the use of curing agent should be increased.

Previous: Quartz Sand (Natural Quartz Stone)

Related Industry Knowledge

- Why does quartz stone crack?(II)

- Why does quartz stone crack?

- Water Mark of Quartz

- How to deal with the color bleeding...

- How to clean quartz tops

- Are Quartz Countertops Worth the Pr...

- The use of inferior quartz stone on...

- How to extend the service life of q...

- Why quartz tops crack

- Quartz Sand (Natural Quartz Stone)

- Two problems in quartz stone

- Environmentally Friendly Composite ...

- The causes and solutions for variou...

- How to clean and maintain quartz st...

- What is quartz

- Quartz processing steps and techniques

- What's the difference between Marbl...

- Quartz stone countertop acceptance ...

- Future of the quartz stone in US

- Hidden dangers and precautions buri...