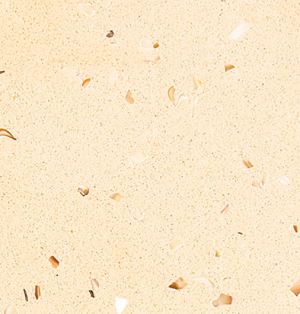

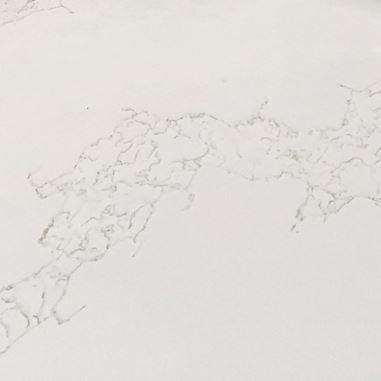

As a new environmentally friendly composite material, quartz stone is made of natural quartz stone particles, micro-powder and unsaturated polyester resin mixed with filler and pigment. Under the action of a small amount of initiator, it is processed by quartz stone manufacturer using special production equipment and surface treatment. Processing, the entire process is completed.

Quartz stone has experienced rapid development in China for more than ten years. The standards of quartz stone industry are increasingly standardized, technology and level are gradually improved, and the variety of products is increasing, but it is also the fierce competition of the industry and the bottleneck of industry development. At present, there are many enterprises in China's quartz stone industry that use small workshops. The quality of artificial stone products produced by small enterprises is relatively poor. Some large enterprises, especially those that do high-end market, still have no problem with the quality of their products. . Some small quartz stone manufacturers blindly pursue low-cost occupation of the market, and the quality has also fallen.

Quartz stone is mainly filled with quartz sand, titanium dioxide and toner. The auxiliary materials are unsaturated resin, curing agent and accelerator. The proportion of the filler is 93%, and the content of the quartz sand is higher than 90%, that is to say, the higher the proportion of the quartz stone plate filler (quartz sand), the better the quality. In addition to the choice and proportion of raw materials, the choice of production and processing equipment is a key factor in determining the quality of quartz stone sheets. The impact of production equipment on quality is also very important. The vacuum value before pressing should reach -99.5 or above to avoid bubbles on the board. The pressing pressure should not be less than 50 tons, so that the density of the sheet can be achieved.

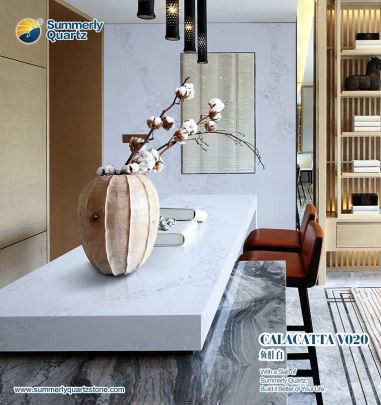

Therefore, under the requirements of this ratio and production process, the price of the finished quartz stone plate will not be too low, and the only way to reduce the price is to reduce the production cost (this should be clear to everyone). I don't think any company will do the loss business, so the price of buying quartz is important but quality is the most important.

Related Industry Knowledge

- Water Mark of Quartz

- How to deal with the color bleeding...

- How to clean quartz tops

- Are Quartz Countertops Worth the Pr...

- The use of inferior quartz stone on...

- How to extend the service life of q...

- Why quartz tops crack

- Quartz Sand (Natural Quartz Stone)

- The reason why the glue of quartz s...

- Two problems in quartz stone

- The causes and solutions for variou...

- How to clean and maintain quartz st...

- What is quartz

- Quartz processing steps and techniques

- What's the difference between Marbl...

- Quartz stone countertop acceptance ...

- Future of the quartz stone in US

- Hidden dangers and precautions buri...

- The influence of Anti-dumping Tarif...

- Bathroom countertop, choose marble ...